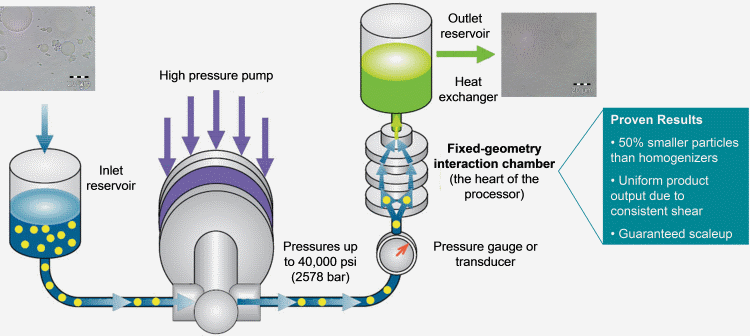

Particle size reduction is the process in which large, solid particles are broken down into smaller particle sizes. This process is often achieved by the use of high shear forces. Particle size reduction is a key process used to transform bulky or randomly sized substances into uniform, small particles suitable for a wide range of applications. When done correctly, particle size reduction favorably alters certain key physiochemical properties of the raw material(s). The success of a given process, such as emulsions and suspensions, often depends on precise size reduction.

- Products

- Lab Scale / Benchtop

- LM10 Microfluidizer

- LM20 Microfluidizer

- M110P Microfluidizer

- LV1 Low Volume Microfluidizer

- M110Y Microfluidizer

- HC Series Microfluidizers

- Pilot Scale Machines

- M110EH Microfluidizer

- M815 Microfluidizer

- Production Scale Machines

- M700 Series Microfluidizers

- MP350 Microlyser™ Processor

- Product Selector

- Which processor is right for me?

- Technology

- Industries

- Applications

- Aftermarket

- Knowledge Hub

- Contact Us